Air Handling Unit AHU

What is an Air Handling Unit (AHU)?

As the name suggests, an Air Handling Unit or AHU is used for handling and subsequently delivering the conditioned air to different parts of a building. For example, a smaller AHU with an airflow volume of 3000 Cubic Feet per Minute (CFM) may be supplying conditioned air to 3-4 rooms within a given building. Whereas, a large AHU with an airflow volume of 45000 CFM may be serving the entire building. Therefore, an Air Handler Unit is chosen based on the HVAC design. The HVAC design may mandate a single AHU for an entire building or the design may require several smaller AHUs to serve different parts of the building.

Where is Air Handling Unit used?

An air handling unit is used in conjunction with a chiller plant / DX Outdoor Units and ductwork.

Chiller Plant >>>>>>> AHU >>>>>>> Supply Ductwork

Outdoor Units >>>>>>> AHU >>>>>>> Supply Ductwork

AHUs can be either ceiling mounted or floor mounted. Ceiling mounted AHUs generally come with a lower airflow volume, typically upto 5000 CFM. Whereas floor mounted AHUs can deliver airflow volume ranging from 1000 CFM to 100000 CFM. AHUs are custom made as per the specific requirements mandated by the HVAC design. A right HVAC design will not only optimize the numbers of AHUs but also optimize the airflow volume of each Air Handling Unit. This optimization of AHUs results in reduction in CAPEX for the client and at the same time delivers optimized OPEX for running the AHUs.

What are the different stages in an AHU?

An AHU consists of several stages. The first stage is that of a grill. The grill is used at the inlet and outlet duct in order to stop foreign objects such as birds, animals, reptiles, or metal objects from entering the main section of the AHU. Thereafter, dampers are installed. The dampers can be fully opened or partially opened or fully closed depending on the fresh air requirements. In case, the return air is circulated fully, then, dampers may be closed fully to stop the entry of fresh air in the AHU. However, in case, the return air is highly concentrated with CO2 or CO or other gasses, then, dampers may be opened fully to allow fresh air to enter the AHU. This way, air quality is maintained. The dampers can be manually operated or fully automated. The next stage in the AHU is that of filters. Filters can be installed in a single stage or multiple stages. For example, for a typical office building, a single stage bag filter is sufficient to remove dirt, dust particles from the air. Whereas for specific operations such as for a testing lab or research and development facilities, multiple stages of filters including HEPA filters are deployed in the AHU to maintain the desired air quality. Filters are periodically cleaned and changed in order to maintain the air quality and at the same time to increase the lifespan of an AHU. The next stage in the AHU is that of a coil. The coil can be a cooling coil or heating coil. The filtered air passes through this coil and then the fan delivers the air to different parts of the building through ductwork. Sometimes, depending on the climatic conditions, an AHU may also incorporate a humidifier/dehumidifier coil. This is how a typical AHU works.

Here is a typical configuration of a standard AHU in India.

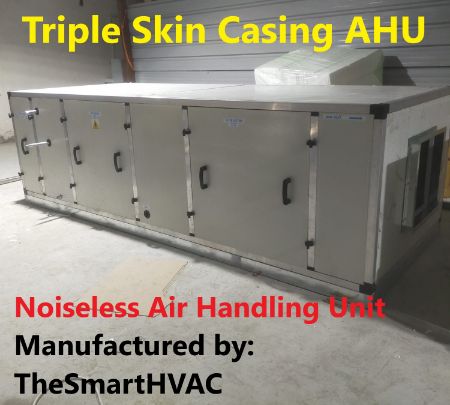

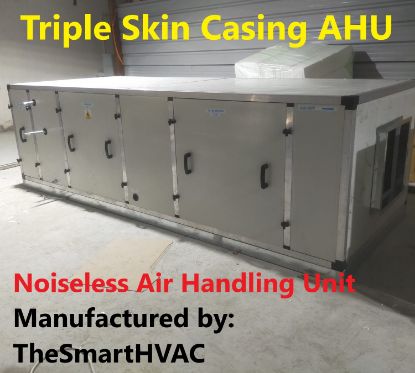

The casing comprises outer skin and inner skin. These skins are made from 0.6 mm to 0.8 mm pre-coated or plain GI sheets. The framework is made from thermal break extruded Aluminum profile with thermal barrier. The unit base is made from a heavy duty GSS fabricated channel. The drain pan is made from 20 G stainless steel with nitrile insulation. This is how the structure of a typical AHU is made in India. Once the structure is constructed, the fan and motors are mounted at appropriate marking. There are a variety of fans that can be chosen depending on the application of the AHU. The common fans available in the marketplace are DIDW/SISW centrifugal backward curved, DIDW backward curved aerofoil blade, SISW plug fan direct driven backward curved fan. Largely belt driven fans are used. However, direct driven fans are also gaining momentum in the Indian marketplace. Bag type, flange type, or HEPA filters are generally used. Anti vibration mountings are used in order to absorb the vibration caused by the fan. The fan diameter can range from 250 mm to 1400 mm. Sometimes 2 large fans are used in the construction of an AHU to deliver the required air volume. Heavy duty motors are used. The coils used in the AHU are typically made from copper.

Innovation

It goes without saying that AHUs are an integral part of any HVAC project. Whether the HVAC system is leveraging a chiller plant or an outdoor unit, the AHUs are used to deliver the conditioned air to different parts of the building. Innovation in AHUs is an ongoing process. Instead of using the standard AC induction motor fan, these days, EC fans (based on BLDC technology) are also being used to manufacture AHUs. These EC fans based AHUs are highly energy efficient.

Focus on energy efficiency is driving the innovation in AHUs. Since AHUs consume a high degree of power, therefore, in addition to deploying EC fans in the AHUs, controls and sensors are also being used to optimize the performance of an AHU. These controls and sensors in conjunction with variable frequency drives control the operation of an AHU resulting in massive reduction in energy bill for the clients. Gone are the days of constant air volume AHUs. Based on the weather pattern and usage pattern, the pressure and air volume of an air handler unit are controlled through the deployment of sensors, drives, and controllers.

TheSmartHVAC with its design-centric approach understands the customer’s requirements thoroughly and based on that the design is prepared.

The AHU selection happens keeping in mind both the CAPEX and OPEX. TheSmartHVAC works with some of the leading AHU manufacturers and we are able to source AHUs at lowest price from these manufacturers because of the economies of scale. This in turn reduces the CAPEX for our clients. Some of the AHU manufacturers that we work with are ZECO, Edgetech, Waves Aircon, Daikin, and many others.

Are you an AHU manufacturer? Partner with us to sell your air handling products to thousands of customers across India. Contact at [email protected]