Bluestar Inverter Ductable AC Hot and Cold

Bluestar Ductable AC Hot and Cold (Available In 5.5 Ton, 8.5 Ton, 11 Ton) Indoor & Outdoor Units. The Bluestar Ductable AC Hot and Cold series provides effective heating and cooling for extreme conditions. Designed for Indian summers and winters, it guarantees maximum performance and energy economy with modern inverter compressor technology. This HVAC system is ideal for anybody looking for consistent year-round temperature management. • Suitable for commercial and industrial applications. • Models include 5.5 Ton, 8.5 Ton, and 11 Ton. • Offers ease of installation, energy efficiency, precise temperature control, and reliability.

Free shipping

Delivery date: 3-5 days

- *

- *

Call for pricing (+91 9650110202)

Key Features of Bluestar Ductable AC:

Inverter Compressor Technology:

- Variable speed for efficient operation.

- Stepless capacity control for uniform cooling/heating.

- 6-pole permanent magnet motor efficiency.

Heat Pump Efficiency:

- Vapor Compression Refrigeration Heater

- It is 4 times more efficient than the available standard electric heaters.

- Suitable for extreme hot/cold conditions.

Advanced Electronic Expansion Valve:

- Geared type design for precise refrigerant flow control.

- In order to improve the response, a PM (permanent magnet) stepper motor is used.

Smart Inverter Drive:

- Refrigerator-cooled PCB for high reliability.

- Operates continuously at 52°C without compressor unloading.

Touchscreen Controller:

- Accurate 0.5°C temperature setting.

- Select mode and fan speed.

- Displays 45 diagnostic codes.

Wider Operating Range:

- Temperature: -10°C to 52°C.

- Voltage: 340V to 460V.

Applications Of Bluestar Ductable Split AC:

Bluestar Ductable Hot and Cold AC systems are suitable for various applications.

Shopping Malls & Retail Showrooms

- Banquet Halls & Restaurants

- Operating Theatres & Hospitals

- Corporate Offices & Meeting Rooms

- Schools

- Industrial Plants

- Theatres & multiplexes

- Resorts & Hotels

Benefits Of Blue Star Ductable Air Conditioner:

- All-Season: Comfort System.

- Single system: For cooling and heating.

- Inverter technology: Enhances heat pump efficiency.

- Lower Carbon Footprint: Eco-friendly heating method.

- Quick ROI: Initial investment recovers in less than a year.

- Quiet Operation: Ideal for sensitive environments.

- Flexible Installation: Longer piping for better placement.

- AHU Integration: Seamless connection with custom Air Handling Units.

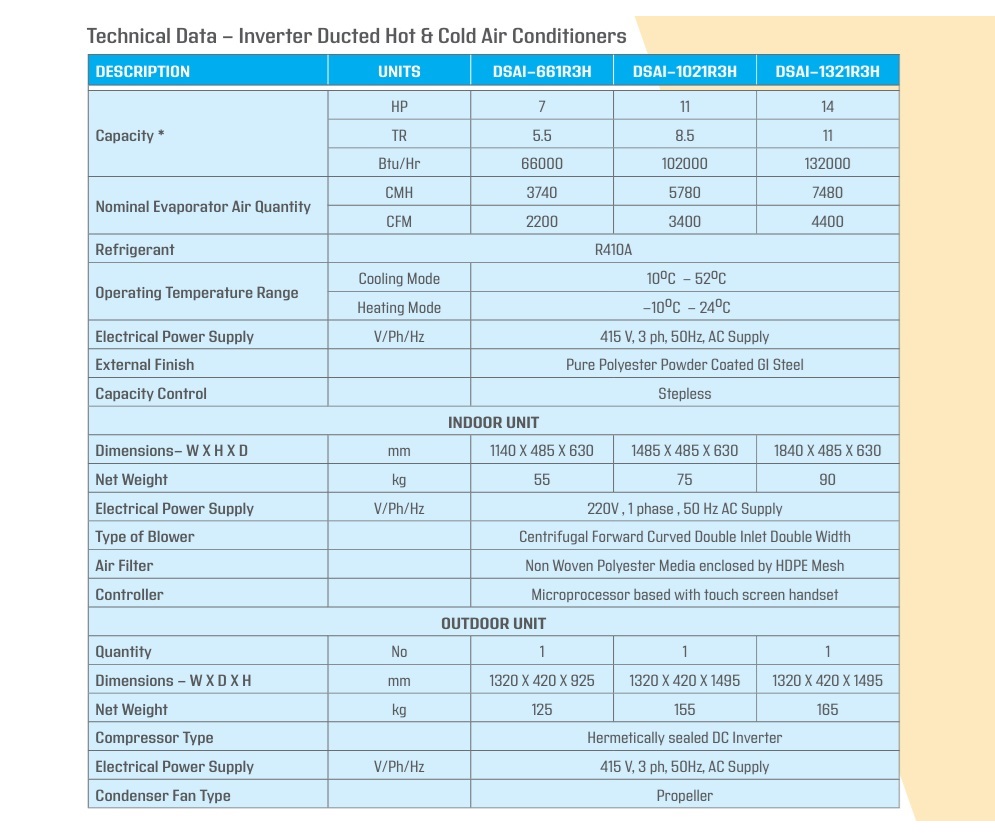

Technical Specifications of Bluestar Ductable AC

Indoor Units of Bluestar Ductable AC:

- Models: DSAI-661R3H, DSAI-1021R3H, and DSAI-1321R3H Models

- Capacity: 5.5, 8.5, 11 tons.

- Airflow: 3740/2200, 5780/3400, 7480/4400.

- Dimensions are: 1140 x 485 x 630, 1485 x 485 x 630, 1840 x 485 x 630.

- Weight: 55, 75, 90 kg.

- Power Supply: 220V, 1Ph, 50Hz.

- Blower Type: Centrifugal Forward Curved, Double Inlet & Width.

- Air Filter: Non-woven polyester with HDPE Mesh.

- Controller: Microprocessor-based, touchscreen handset.

Outdoor Units of Bluestar Ductable AC:

- Models: DSAI-661R3H, DSAI-1021R3H, DSAI-1321R3H.

- Dimensions: 1320 x 420 x 1495.

- Weight: 125, 155, 165 kg.

- Compressor: Hermetically sealed DC Inverter.

- Power Supply: 415V, 3Ph, 50Hz.

- Condenser Fan: Propeller Type.

- Refrigerator: R410A.

- Operating Temperatures (Cooling): 10°C to 52°C.

- Operating Temp (Heating): -10°C to 24°C

What Makes the Bluestar Ductable Air Conditioner a Good Choice?

- Leading brand with decades of experience and strong R&D.

- Offers customizable solutions in 5.5-ton, 8.5-ton, and 11-ton capacities.

- Features powder-coated GI steel housing for durability.

- The company offers 24/7 customer care with an extensive service network across India.

- Features an aesthetic, functional touchscreen controller for enhanced user experience.

Blue Star Ductable AC Prices:

- Call Now for Blue Star 5.5 ton hot and cold ductable AC price

- Blue Star ductable AC hot and cold 8.5-ton Price: Call for prices

- Blue Star hot and cold 11-ton ductable AC Price: Call for pricing

How To Install Bluestar Ductable AC:

A ductable split AC, such as the Bluestar Inverter Ducted Hot & Cold, requires precise installation to guarantee optimal performance and longevity.

- Planning Before Installation:

Check Capacities:

Before installing a Blue Star ductable AC 5.5 ton, consider the room size, heat load, and insulation to determine the appropriate tonnage (5.5, 8.5, or 11).

Ductwork Layout Scheduling:

To guarantee a constant air distribution, the return and supply ducts' airflow paths should be built using computational fluid dynamics (CFD) ideas.

The System of Electrical:

- Conversely, the inner unit should only have a supply of one phase (220V), whereas the exterior unit is supposed to have a supply of three phases (415V). Certainly, this is the case compared to the central unit, which should only have one phase of supply. The outer unit requires a three-phase power supply to function properly. When contrasted to the inner unit, this is a different setup.

- As a result, it is critical to ensure that all necessary MCBs and ELCBs are properly configured.

- Installing Indoor Units:

- Installation could take place either in the utility room or on top of the false ceiling. Both options are feasible. Both choices are available for consideration. Neither of these two places limits other options.

- It is of the utmost importance to guarantee that the joints are properly sealed off from the air throughout the duct system building process by making sure they are sufficiently sealed off.

- One of the most important aspects of the process is the design of the interface, which will allow the touch controller and the non-woven filter to interact efficiently.

- We must ensure that the appropriate manner will guide future service clearance so we can keep our promise.

- Installing Outdoor Units:

- Use a solid foundation and, if possible, vibration-reducing mounts.

- To protect the gadget from being stuck in limited spaces, ensure that it has adequate ventilation from all directions.

- When something needs to be installed at a great distance, it is best to use very long pipe alternatives (up to sixty meters horizontally and twenty meters vertically).

- Electrical Wiring and Refrigerant Piping

- Ensure best performance by using suitably insulated copper refrigerant lines.

- The drainage pipe has to slope appropriately to avoid water collecting within.

- Use signal wires to link the devices inside and outside the house.

- Insulation resistance testing and grounding checks are duties to be carried out.

- Testing and commissioning:

- Vacuuming the lines after they have been linked can help to eliminate any air or moisture in the lines carrying the refrigerant.

- The amount of refrigerant charged is determined by whether or not it is required; in the case of compliance, the length of the pipe is evaluated.

- It is important to check the temperature setting once the power has been switched on to see if the energy is heating or cooling the area.

- In addition to selecting the control mechanisms that will be employed, you must also examine the levels of noise, temperature, and air flow.